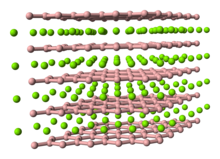

Titanium diboride

Titanium diboride (TiB2) is an extremely hard ceramic which has excellent heat conductivity, oxidation stability and resistance to mechanical erosion. TiB2 is also a reasonable electrical conductor, so it can be used as a cathode material in aluminium smelting and can be shaped by electrical discharge machining. Titanium diboride (TiB2) is an extremely hard ceramic which has excellent heat conductivity, oxidation stability and resistance to mechanical erosion. TiB2 is also a reasonable electrical conductor, so it can be used as a cathode material in aluminium smelting and can be shaped by electrical discharge machining. TiB2 shares some properties with Boron Carbide & Titanium carbide, but many of its properties are superior to those of B4C & TiC: With respect to chemical stability, TiB2 is more stable in contact with pure iron than tungsten carbide or silicon nitride. TiB2 is resistant to oxidation in air at temperatures up to 1100 °C, and to hydrochloric and hydrofluoric acids, but reacts with alkalis, nitric acid and sulfuric acid. TiB2 does not occur naturally in the earth. Titanium diboride powder can be prepared by a variety of high-temperature methods, such as the direct reactions of titanium or its oxides/hydrides, with elemental boron over 1000 °C, carbothermal reduction by thermite reaction of titanium oxide and boron oxide, or hydrogen reduction of boron halides in the presence of the metal or its halides. Among various synthesis routes, electrochemicalsynthesis and solid state reactions have been developed to prepare finer titanium diboride in large quantity. An example of solid state reaction is the borothermic reduction, which can be illustrated by the following reactions: (1) 2 TiO2 + B4C + 3C → 2 TiB2 + 4 CO (2) TiO2 + 3NaBH4 → TiB2 + 2Na(g,l) + NaBO2 + 6H2(g) The first synthesis route (1), however, cannot produce nanosized powders. Nanocrystalline (5–100 nm) TiB2 was synthesized using the reaction (2) or the following techniques: Many TiB2 applications are inhibited by economic factors, particularly the costs of densifying a high melting point material - the melting point is about 2970 °C, and, thanks to a layer of titanium dioxide that forms on the surface of the particles of a powder, it is very resistant to sintering. Admixture of about 10% silicon nitride facilitates the sintering, though sintering without silicon nitride has been demonstrated as well.